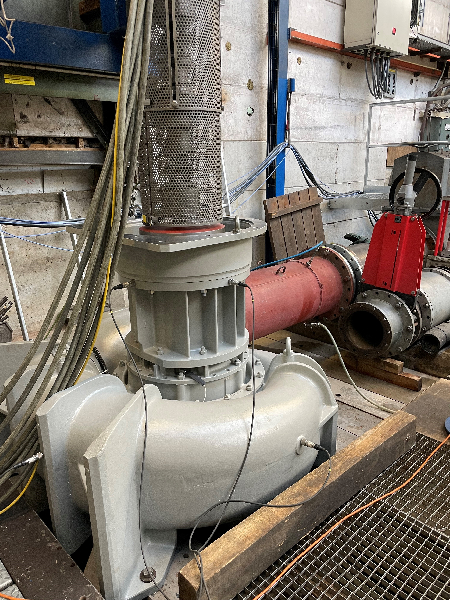

Extensive test programs tailored to each pump, ensures the mechanical integrity of complete systems and makes sure that the pump leaves the factory in perfect ready-to-operate condition.

Verification and confirmation of hydraulic, nechanical and electrical performance ensures safe and reliable operation. Extensive test programs, tailored to each pump, ensure the mechanical integrity of complete systems and ensure that the pump leaves the factory in perfect, operational condition. These test programs typically include a complete, practical test run under the conditions agreed upon in the contract. These normally include running, measuring mechanical and hydraulic power as soon as stable operating temperatures are achieved, variable speed ranges, warranty points and shutdown.

Pumps can be tested to various industry standards including ISO 9906 and ANSI/HI (Hydraulic Institute) 11.6. Hidrostal instrumentation is calibrated on a regular basis.

Factory testing is available in our production sites in Switzerland, Peru, United Kingdom, Hungary and China.

Test types: